Product Lines

MASTERING SYSTEM DIVERSITY

Systems engineering to develop a product line

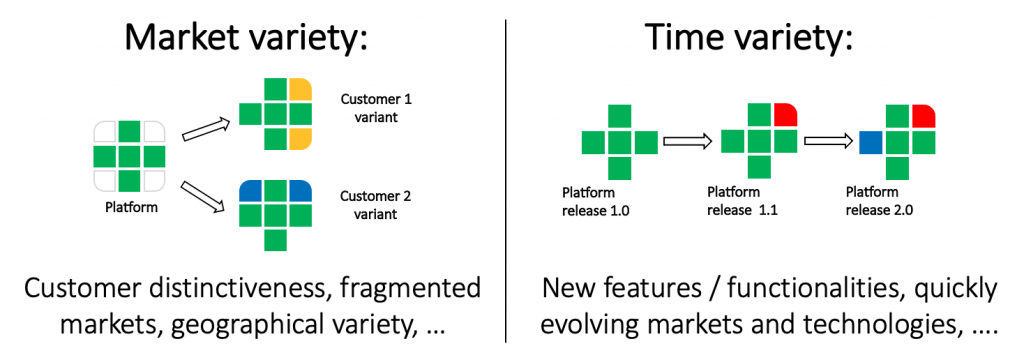

A product line is an architectural strategy for designing, developing, and managing a set of similar systems or products based on a common core (platform) and configurable or variable modules, thus providing variety at lower cost.

| What are the pitfalls when developing a product line?

Many companies are implementing a product line/platform approach, seeking to offer variety while pursuing ambitious business objectives:

➤ Cost savings: reduced development costs, economies of scale, inventory reduction.

➤ Revenue benefits: faster time to market, penetration of niche markets.

➤ Risk benefits: reduced technological risks, higher quality.

But developing a product line can lead to:

➤ Costly generation of new variants or versions: complex, non-modular, and non-scalable platform.

➤ Poor industrial performance: high costs and PPM, long lead times and ramp-up times.

➤ An explosion of diversity: over-customization, proliferation of components.

➤ Local optimization project by project: lack of an overall market and product strategy.

Key features of the product line:

➤ Main objective: Reduce recurring and non-recurring costs, shorten time to market, and increase customer satisfaction.

➤ Fundamental principle: Standardize what’s hidden, customize what’s visible.

➤ Structuring: Implement a modular architecture with standardized interfaces and centralized platform governance.

➤ PBS 150% approach (Product Breakdown Structure): Includes all possible options, a portion of which is selected for each specific product.

➤ Reusability and variability: Maximize component reuse while allowing for the customization of variants.

| The product line approach delivers sustainable value and ensures the company achieves its business objectives through a structured approach

Our integrated approach is based on 3 complementary axes to deliver the full value of a modular product line/platform approach.

Reduce recurring and non-recurring costs

A product line approach makes it possible to drastically reduce development costs (-60% in the software industry), customization engineering costs (-50% in the aeronautics industry) and inventory costs (€10 million/year in the computer server industry).

Reduced time to market

A product line approach allows reducing variant generation time (from 200 days to 4 days in the defense industry), shortening time to market (-50% in the elevator industry) and reducing order-to-product time (-75% in the computer server industry).

Reduce diversity

A product line approach helps reduce component variability (up to -83% in the computer server sector) and increase software module reuse (from ~7% (before) to 90% (after) in the software sector).

||||| Resources

DOCUMENT [EN]

CESAM Key Takeaways for Product Lines

The purpose of the product line approach is to identify variabilities (propagating from external reasons, of related to internal reasons of the enterprise), and optimize them in order to be more efficient when generating products variants.

Learn key concepts with this one-page memo on system architecture for the product line.

Webinaire [EN]

Systems Engineering and Product Line Approach

In this webinar, Oussama CHERIF, Innovation Director of Intralogistics Business Units at Fives provides insights on how a systems engineering and product line approach are essential levers to support international growth, scale-up and standardization of intra-logistics solutions, and presents technological / organizational impacts of such a transformation.

Fives, an international industrial engineering Group

Fives designs and supplies machines, process equipment and production lines for the world’s largest industrial players. Fives supports its customers throughout the entire lifecycle of their equipment, from commissioning to revamping. This includes design, supply, installation, service and maintenance.

Webinaire [EN]

How a Product Line – Modular Platform approach drastically reduces costs and time to market?

The current context forces companies to be more efficient. Many firms implement product line – modular platform approach seeking to deliver variety while pursuing ambitious business objectives. But despite the undisputed and significant benefits of a such an approach, companies fail to efficiently develop it if they do not have an architecture driven and company-wide approach.

In this webinar, we address the following topics: presentation of real industrial cases studies, fundamental principles of a Product Line – Modular Platform approach (technical, operational, organizational), key insights to concretely put a Product Line – Modular Platform approach into practice