Product Lines Architecture

Description

Industrial organizations and manufacturers of complex products and services now face fragmented markets where each segment is characterized by fierce competition and a high level of specificity demanded by customers and end users. There is therefore a real competitive advantage in being able to offer products that best meet the needs of customers and end users at a controlled cost.

Our training addresses this industrial challenge: how to create tailor-made products while controlling costs and risks? You will learn how to optimize the reusability of existing components while managing the diversity of a product family/line, which leads to flexible and modular architectures.

Training Objectives:

Upon completion of this training, you will be able to:

— Understand the challenges, challenges, and foundations of modular architecture

— Implement, in practice, an operational, functional, and organic architecture approach within the context of a product family or line

— Understand the strategic, managerial, organizational, and financial impacts of implementing a product family or line policy

Target audience: engineers and project managers, managers, and directors

Prerequisites: at least two years of experience in the design and management of complex industrial products and knowledge of the fundamentals of system architecture

Methods & curriculum: We dedicate a large portion of our modules to discussions and interaction with trainees, but above all, to practical training to facilitate learning. Over two days, you will immediately put your acquired knowledge into practice through exercises applying the agile architecture approach to product development.

Information

DURATION

14 hours (2 days)

9:00 a.m.–12:30 p.m./1:30 p.m.–5:00 p.m.

TRAINING MATERIAL

Electronic version sent prior to the training

TRAINER

A senior architect

FORMAT

Inter-company or intra-company

LOCATION

Online or CESAMES Academy (Paris)

PRICING

Inter-company: €2,000 excluding VAT / person (Includes lunches)

Intra-company: Quote upon request

MONITORING

Attendance sheet and certificate of completion

EVALUATION

Training quality assessment and satisfaction questionnaire at the end of the module

CESAMES Academy

Email : academy@cesames.net

Program

JOUR 01

0. Module Introduction

1. Overview of Product Families and Lines

2. Architecture of a Product Family/Line

– Fundamentals of System Architecture

– Operational Architecture

– Exercise: Stakeholder Analysis

– Functional Architecture

– Constructional Architecture

– Summary: Alignment Between Different Architecture Layers

– Exercise: Constructional Decomposition

JOUR 02

3. Variability Analysis and Optimization

– Variability Identification

– Exercise: Variability Identification

– Modularization & Decoupling

– Variability Optimization

– Exercise: Variability Optimization

4. Managing a Product Family/Line

– A New System of Interest: The Company

– Sponsoring a Transformation to a Product Line Organization

– Analysis of the Current Company

– Definition of the Target Company

– Focus on the Industrial System

– Exercise

Resources

DOCUMENT [EN]

CESAM Key Takeaways for Product Lines

The purpose of the product line approach is to identify variabilities (propagating from external reasons, of related to internal reasons of the enterprise), and optimize them in order to be more efficient when generating products variants.

Learn key concepts with this one-page memo on system architecture for the product line.

Webinar [EN]

Systems Engineering and Product Line Approach

In this webinar, Oussama CHERIF, Innovation Director of Intralogistics Business Units at Fives provides insights on how a systems engineering and product line approach are essential levers to support international growth, scale-up and standardization of intra-logistics solutions, and presents technological / organizational impacts of such a transformation.

Fives, an international industrial engineering Group

Fives designs and supplies machines, process equipment and production lines for the world’s largest industrial players. Fives supports its customers throughout the entire lifecycle of their equipment, from commissioning to revamping. This includes design, supply, installation, service and maintenance.

Webinar [EN]

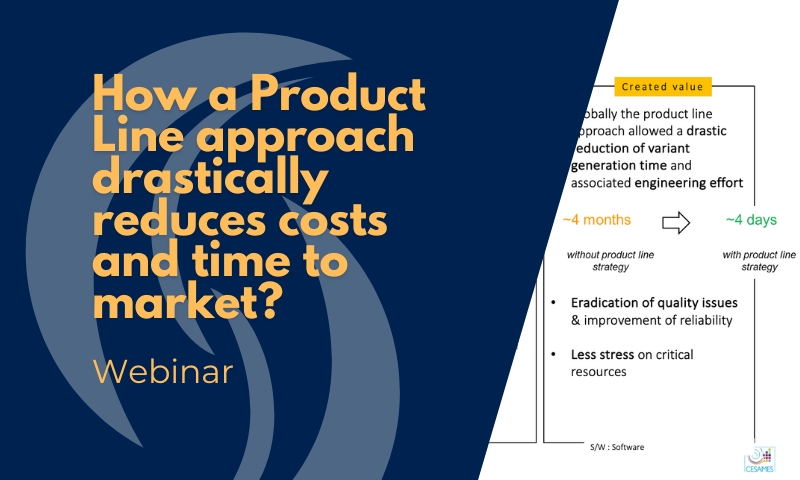

How a Product Line – Modular Platform approach drastically reduces costs and time to market?

The current context forces companies to be more efficient. Many firms implement product line – modular platform approach seeking to deliver variety while pursuing ambitious business objectives. But despite the undisputed and significant benefits of a such an approach, companies fail to efficiently develop it if they do not have an architecture driven and company-wide approach.

In this webinar, we address the following topics: presentation of real industrial cases studies, fundamental principles of a Product Line – Modular Platform approach (technical, operational, organizational), key insights to concretely put a Product Line – Modular Platform approach into practice